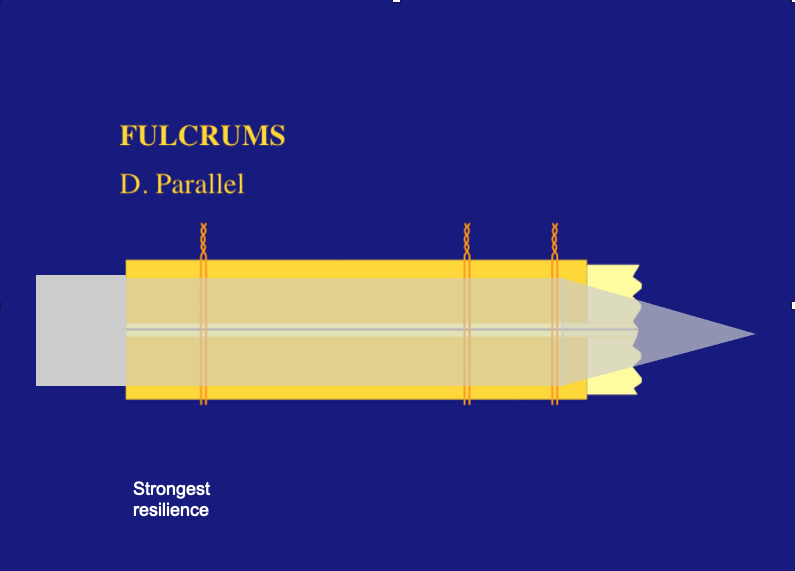

Parallel Fulcrum Procedure

A tube with a parallel fulcrum is a tube where the height at each wire is roughly the same. For example, if the height at wire I is 5mm, the height at wire II and wire III would also be 5mm. The parallel fulcrum provides the strongest resilience.

The procedure to make a parallel-fulcrum tube is simple. When forming the blank, use a forming mandrel that is not tapered (conical), but is straight, with the same diameter at each of the wire positions. (Of course, the mandrel may have a pointed tip that extends beyond wire I.) The forming mandrel may have a diameter of about 4.25mm (roughly 11/64 inches); this could be a greater or smaller diameter for a tube shape that is particularly wide or narrow. A single-pointed knitting needle can be used; these are available in a range of diameters.

Insert the forming mandrel and place all 3 wires. As a final step in forming, use pliers to squeeze the blank from top to bottom (not from side to side), so that the inside height of the tube conforms to the surface of the mandrel. As with any forming process, never squeeze from side-to-side between wires I and II. This blank will require more reaming than a blank made with a conical fulcrum.